MDF or Wood?

Painted baseboards, window and door casings can make a big difference in the overall look and feel of your space. Many people ask about the difference between MDF and wood. This summary should help you make an informed decision.

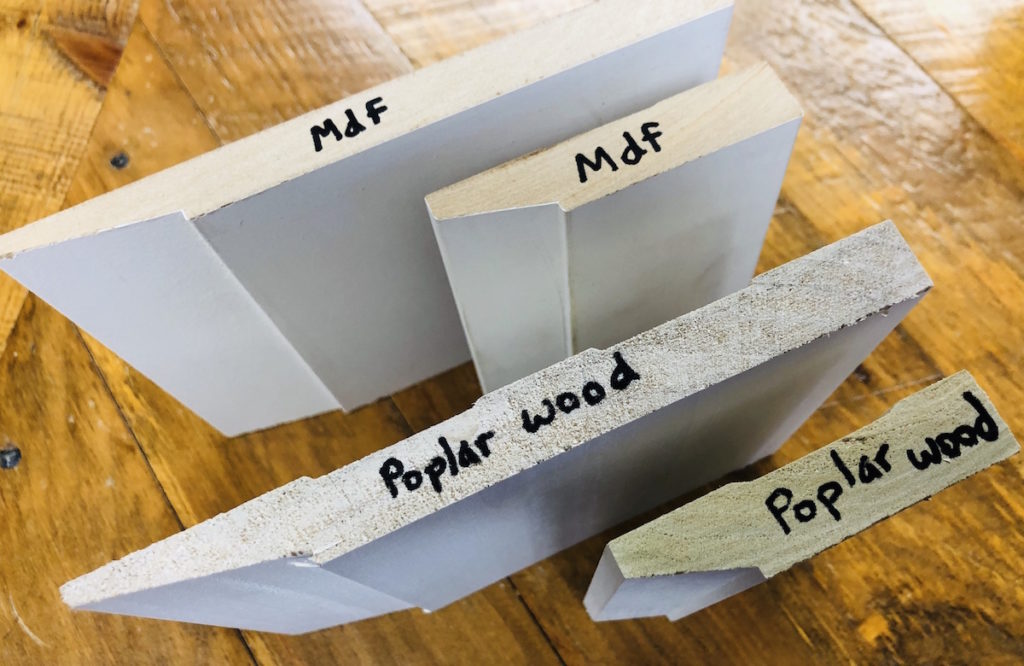

MDF

MDF is medium density fiberboard and usually made offshore. MDF is a very cost effective material for baseboard and casings. MDF has zero imperfections. It is always primed and ready for paint. MDF and has zero warps or twists in the material. However, MDF is soft and less durable over time. The extra fine dust created during cutting and installation can be hard to clean and unhealthy to breathe. Another important consideration with MDF is that the nail holes are more difficult to fill properly in comparison to Poplar. It is difficult to repair MDF if it gets damaged.

Some people refuse to work with MDF, while others love it. If you want to try it, make sure you buy CARB compliant MDF. Some offshore MDF moulding manufacturers have harmful carcinogenic substances in the MDF. All our MDF mouldings and dimensional boards are CARB compliant.

Wood

The most commonly used wood material for trimwork is Poplar and primed Finger Jointed Pine. Baseboards and door casing can take a beating over time. Poplar is a hardwood, which makes it an excellent material because it is so durable over time.

Finger Jointed Pine is also available as a slightly more cost-effective, economy grade wood solution. Finger Jointed Pine is often made offshore and usually pre-primed. However, being a softwood, Finger Jointed Pine is less durable than Poplar and more susceptible to moisture changes in the air than Poplar.

So when choosing your wood, bear in mind that Poplar has more enduring qualities than Pine.

Cost Vs Quality Trade Off

There may appear to be a significant price difference between Poplar and MDF. However, once you take into consideration the price for installation and painting, the overall cost savings are less significant.

Industry Attitude Towards MDF

Over the years the industry has slowly and cautiously adopted MDF into their building products. Now it is commonly accepted as a suitable material for many applications.

Some applications are better than others. For example, the kitchen industry has widely adopted the use of MDF doors due to their overall stability, and their ability to customize with modern CNC equipment. Most kitchen manufacturers, even high-end ones, are using and promoting MDF doors over wood when painting the doors solid colours.

In Summary

When painting your trimwork it is recommended to use either Poplar or MDF.

Both MDF and Poplar paint very evenly and are both very stable products. Some contractors prefer to work only with one or the other.

Poplar Wood Pros:

- Poplar is harder, lighter in weight, and more durable over time.

- Poplar often has deeper cut profiles which provide more defined lines, and thicker profiles.

- Available primed white in most in stock profiles.

- Nail holes are easier to fill and finish more evenly.

- Ability to order smaller quantities in custom shapes with quick lead times.

- Our Poplar is manufactured in Bradford, Ontario at Alexandria’s Royal Woodworking plant.

MDF Pros:

- Very consistent quality in milling and finish and there are no natural defects

- Always primed and ready for paint

- Very processed which makes it very stable so no warps and it lies flat

- More cost-effective than wood

- All our MDF is phase 2 California compliant & formaldehyde free

The above list of characteristics should help you make your decision on whether to opt for MDF or wood on your next project.

We’re always happy to see you in our showroom or you can contact us for more information. If you need some help working out what you need, we can provide an on-site material estimate and quotation service.

Thank you!

Your welcome!