Trim & Mouldings Catalogue

Design & decorate with stunning architectural trim & mouldings from The Royal Wood Shop

We have over 200 styles of trim and mouldings in stock and ready to ship in Toronto and throughout the GTA. Browse our massive trim & mouldings product catalogue! Can’t find a product in our catalogue?

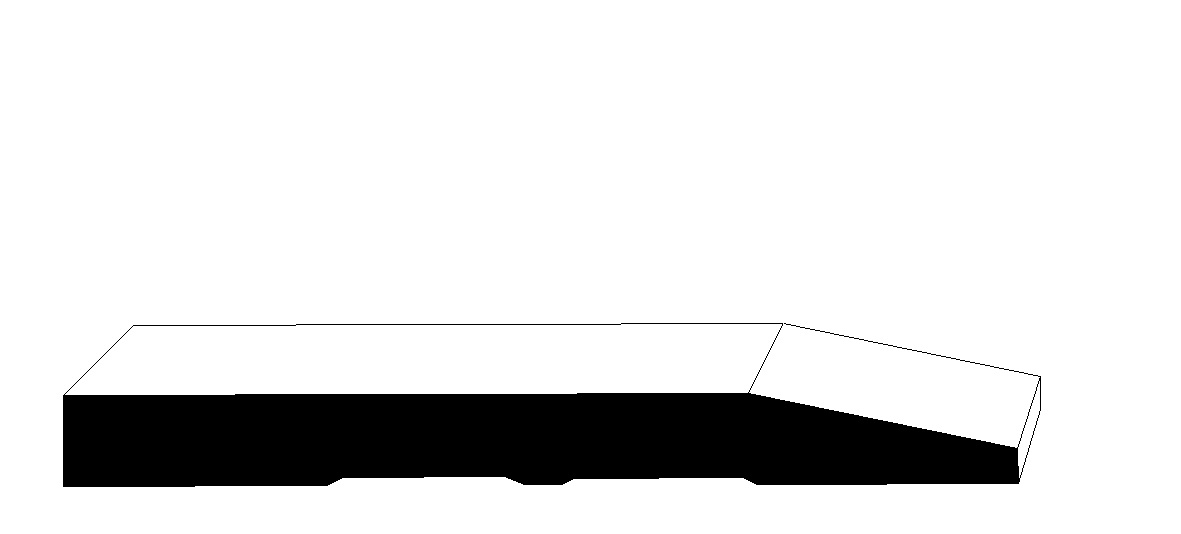

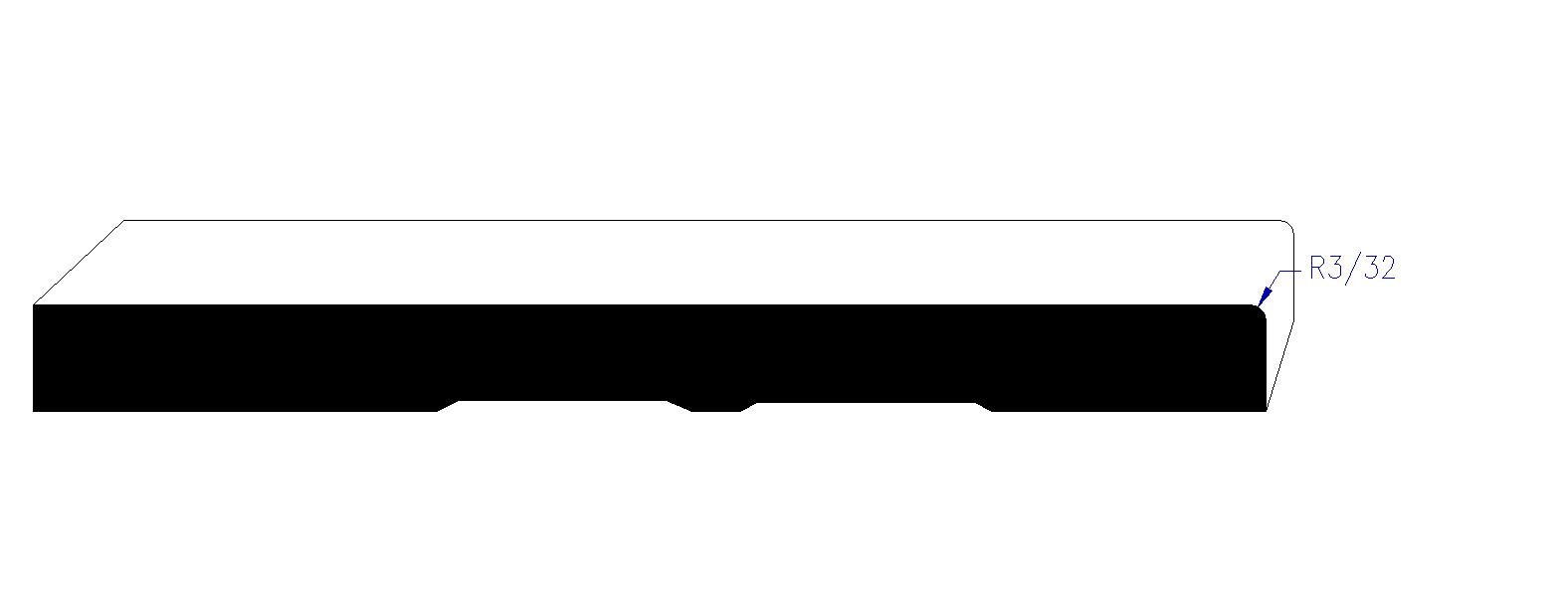

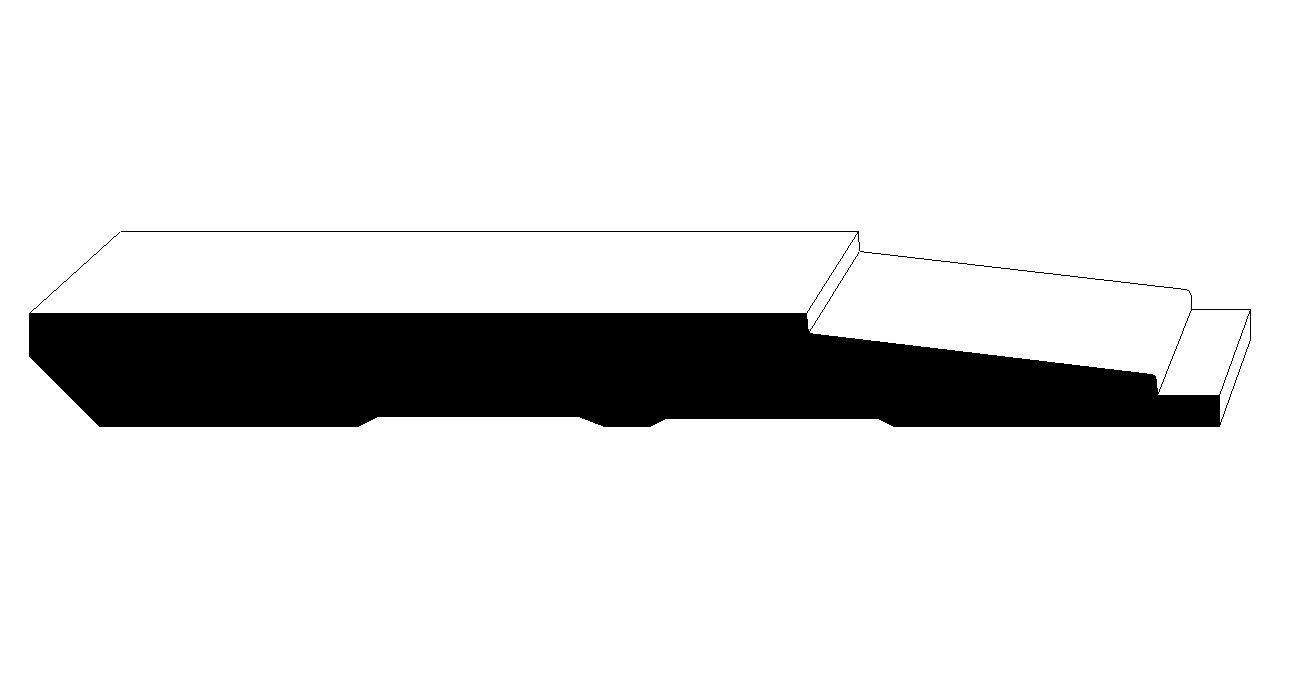

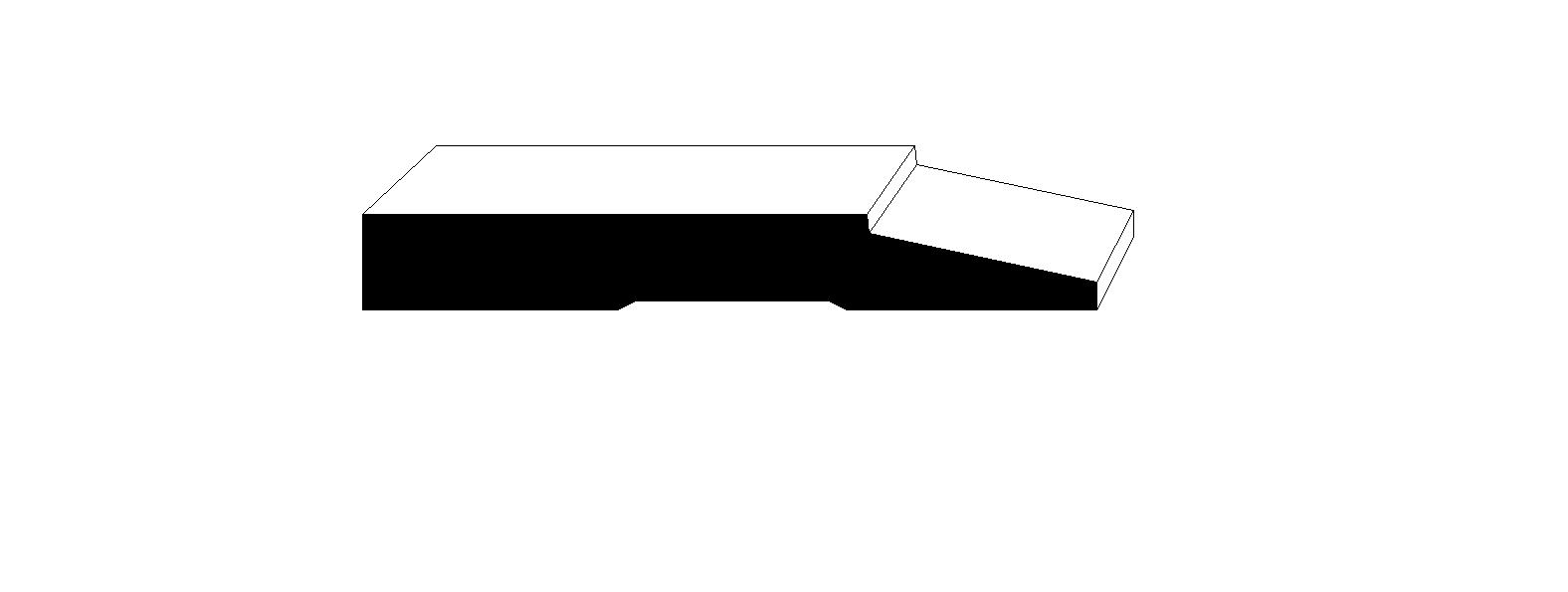

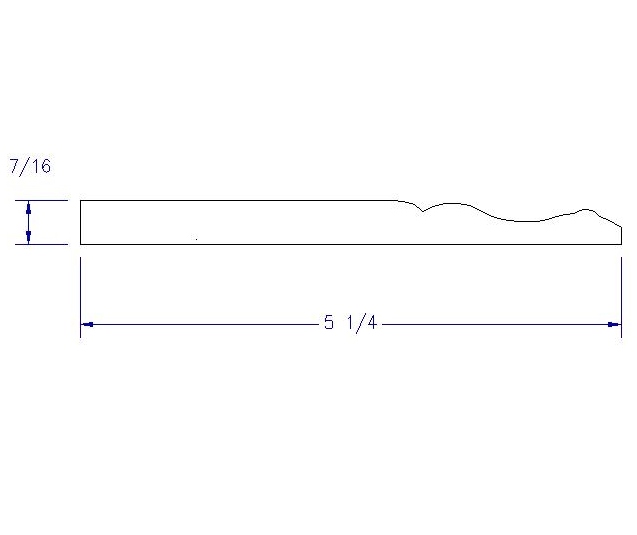

Primed Horizontal Ship Lap tongue and groove with a 1/4″ gap for a very modern effect. This product also has a nailing line so you don’t see nail holes (or have to fill them!)

Primed Horizontal Ship Lap tongue and groove with a 1/4″ gap for a very modern effect. This product also has a nailing line so you don’t see nail holes (or have to fill them!)

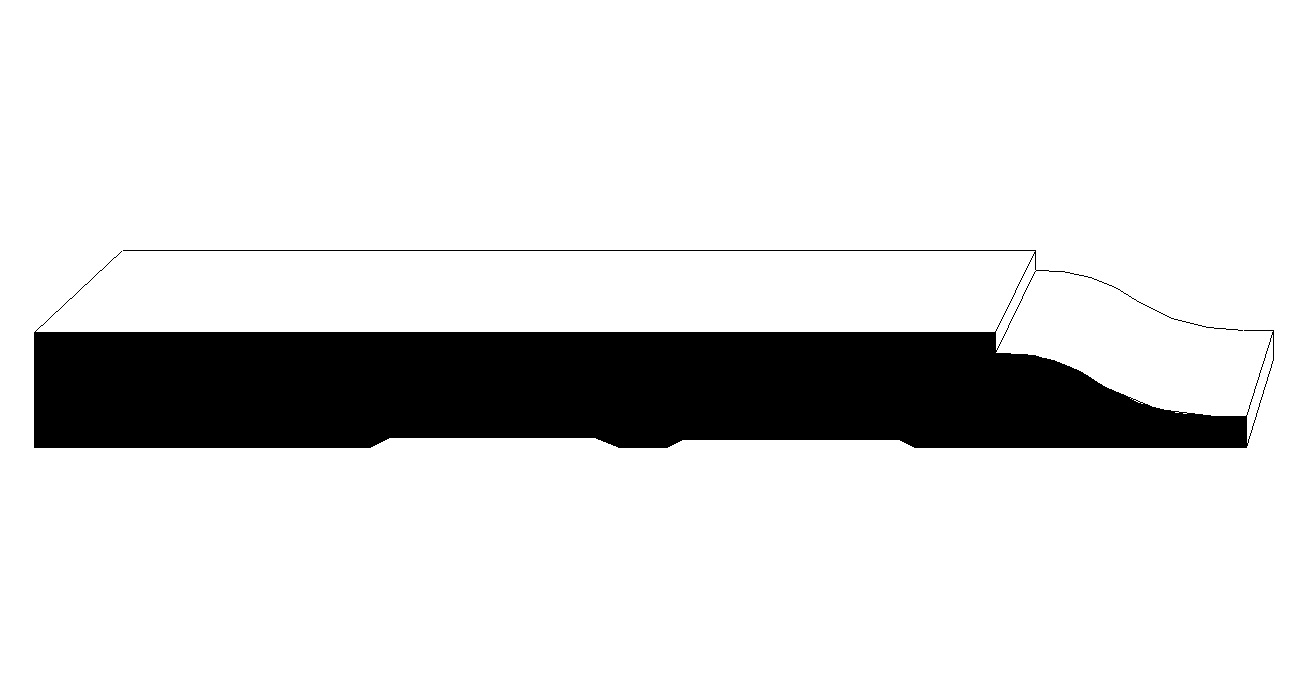

T&G is applied to walls and ceilings for a decorative paneled look. Lengths are 8′ and 16′ long and the material comes primed white ready for a finished coat after installation.

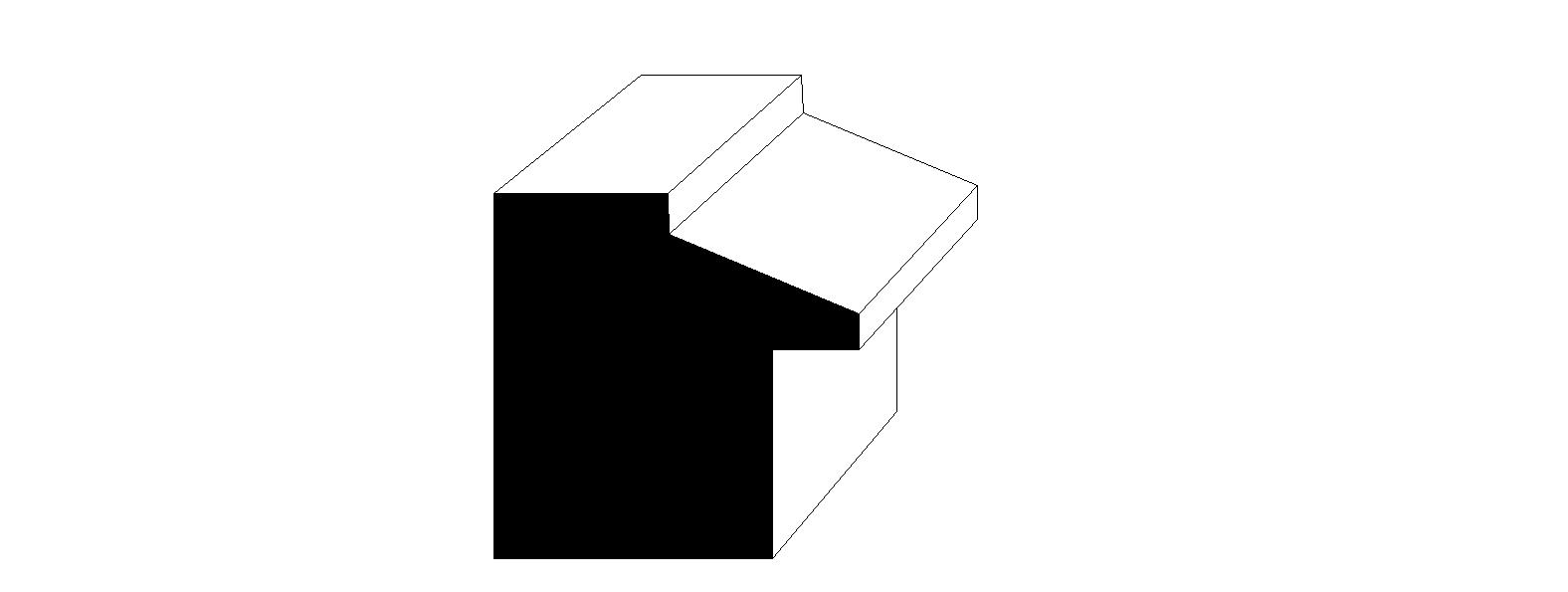

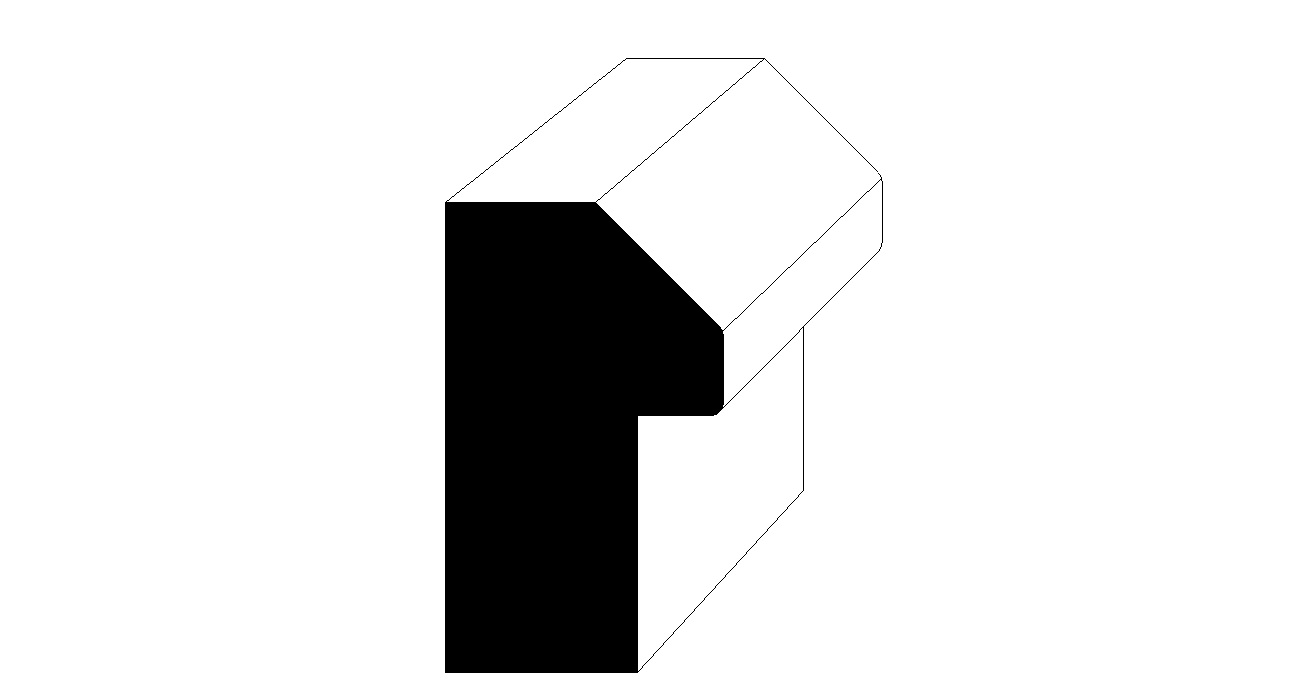

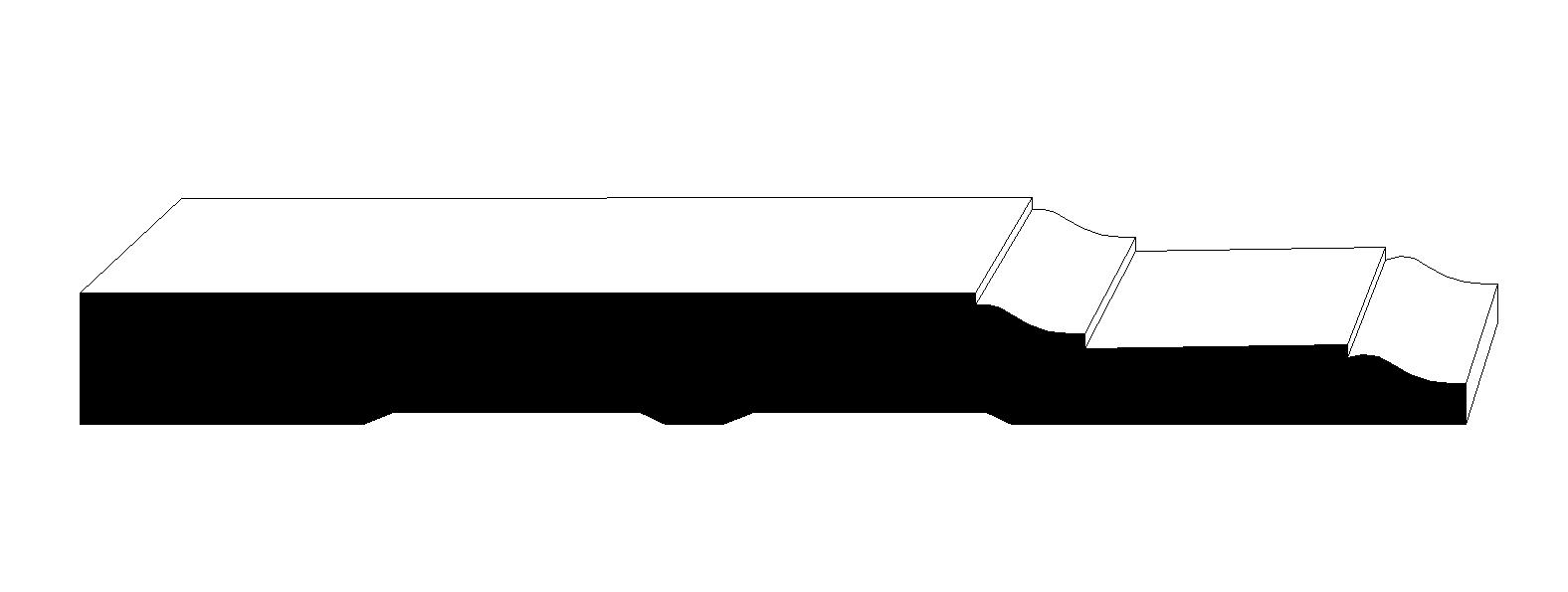

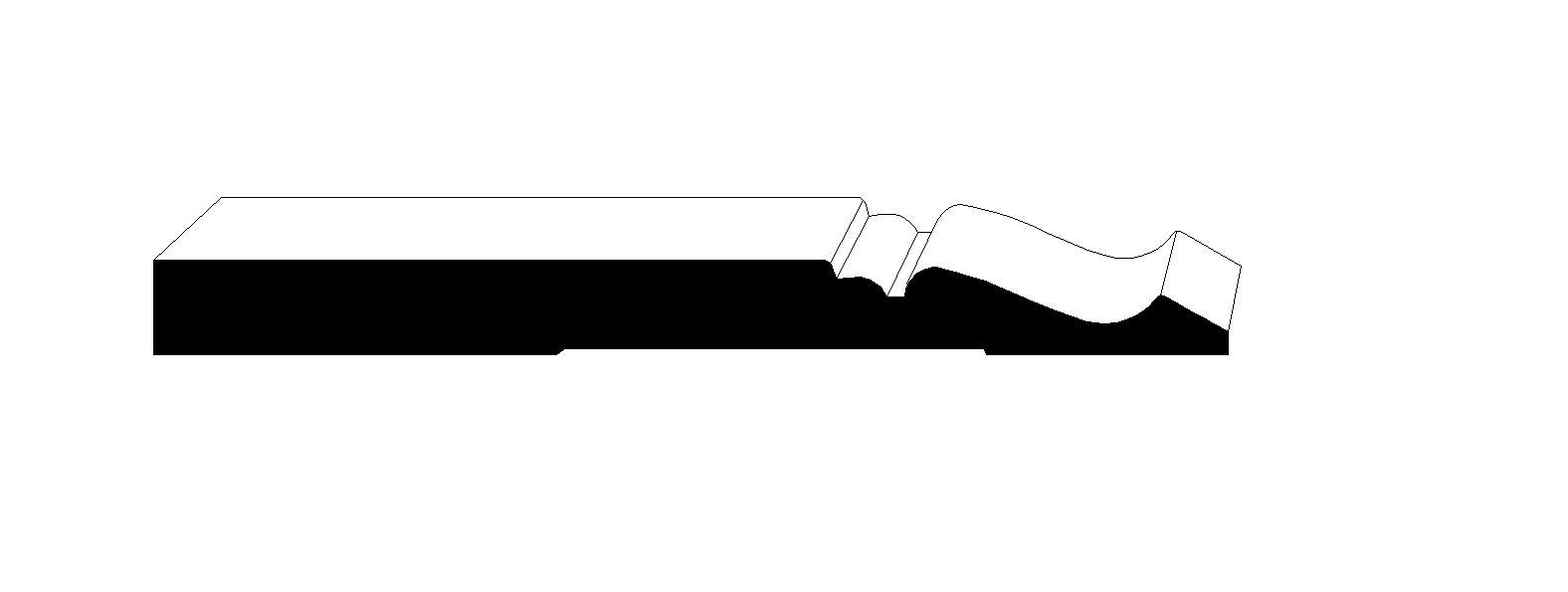

This is a one piece architrave is also called a pediment or a door header. It is the top horizontal trim piece over the door or window. It will be wider and thicker than the casing. You do not mitre the casing around the door when you use architrave. The casing comes up each side of the door and butts into the bottom of the architrave. Architrave moulding is a very classic look and can come as a one piece mould, or often built up out of three or more separate trim pieces.

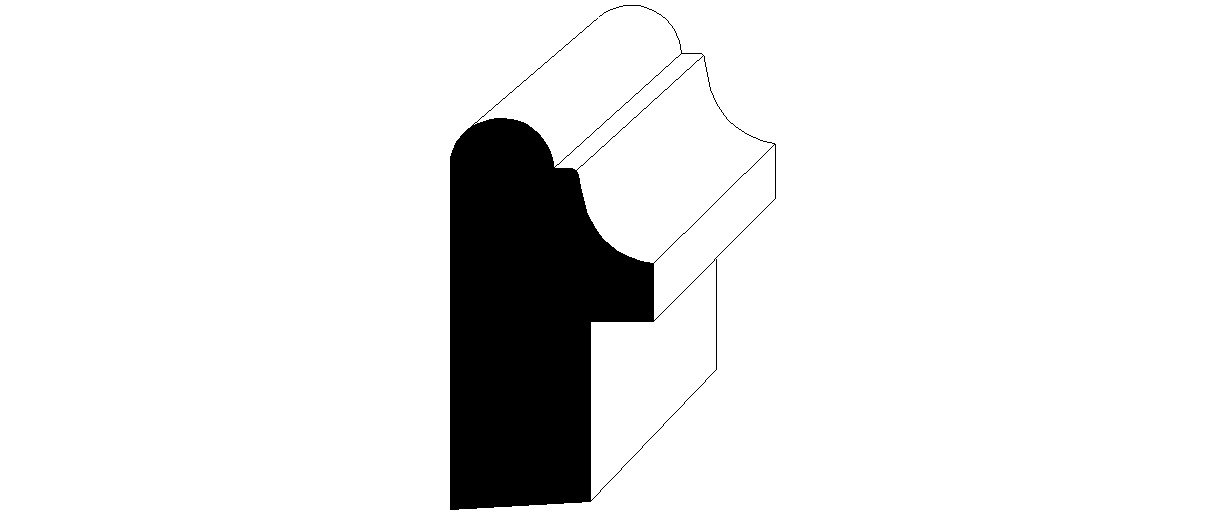

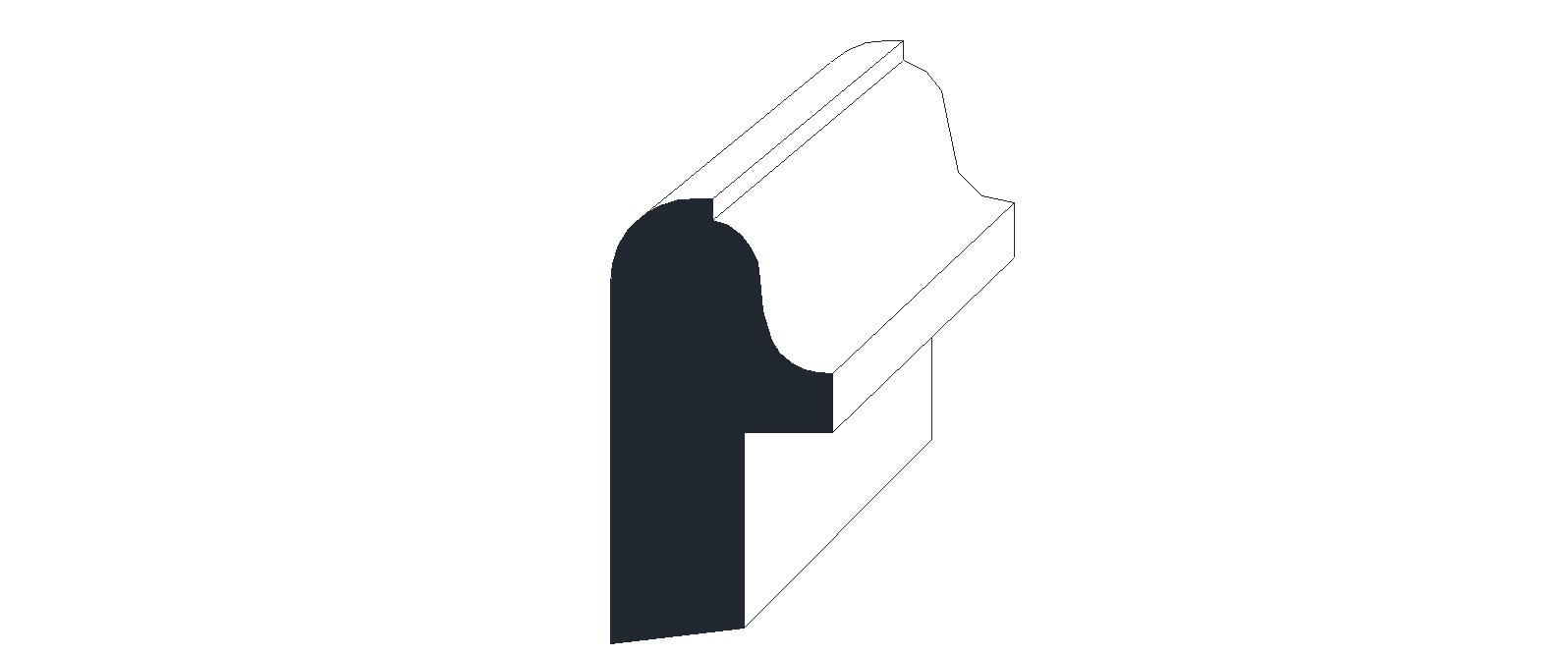

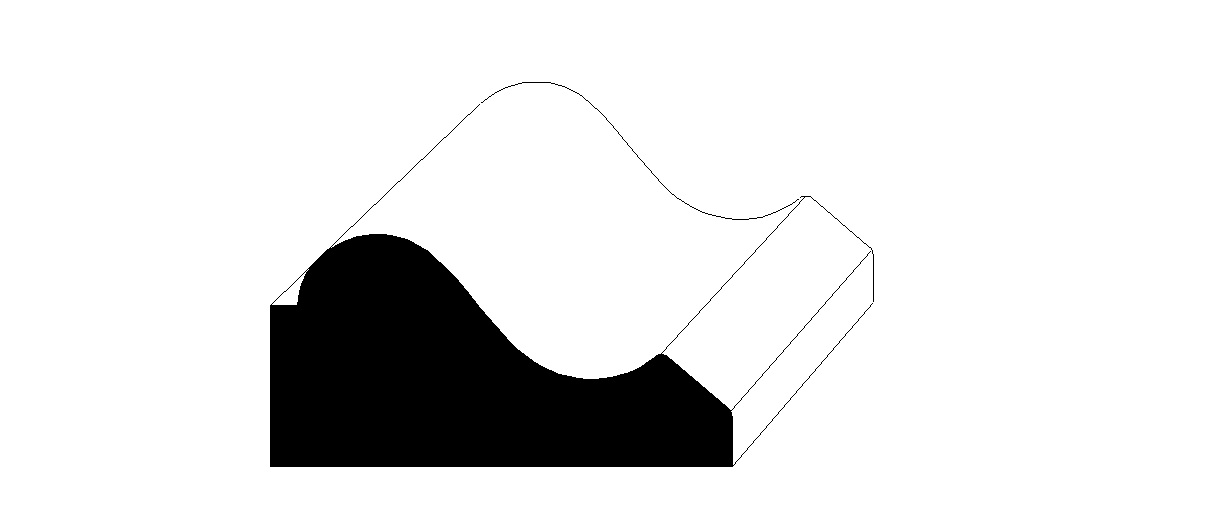

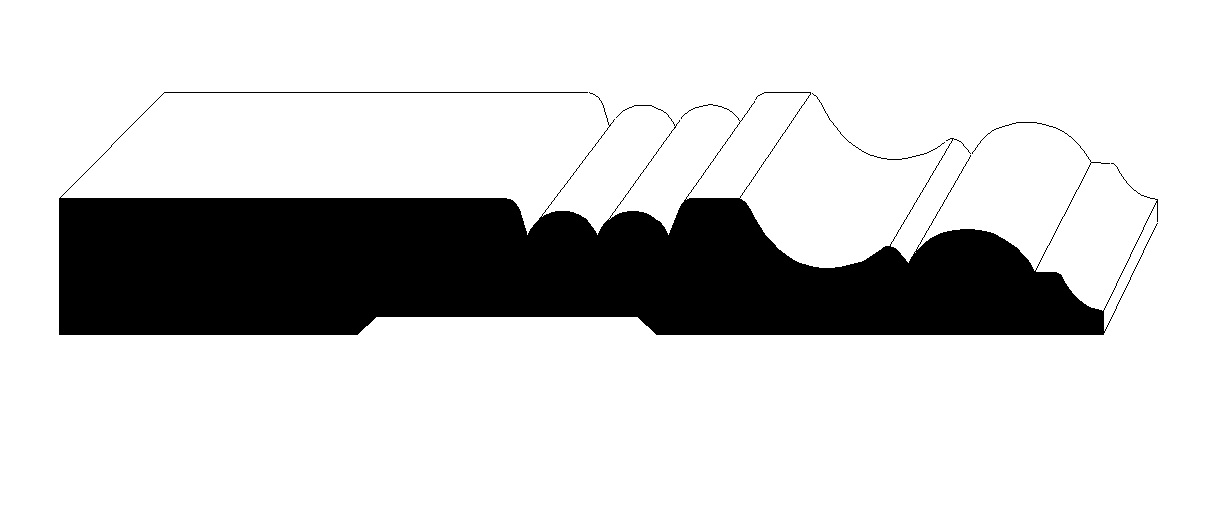

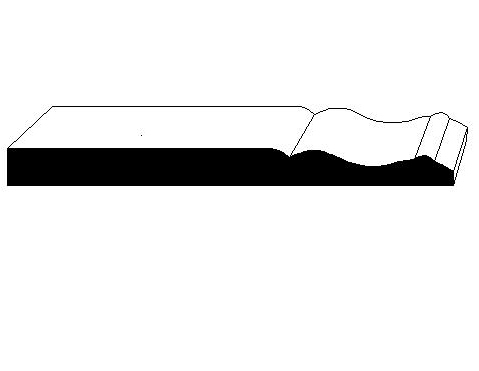

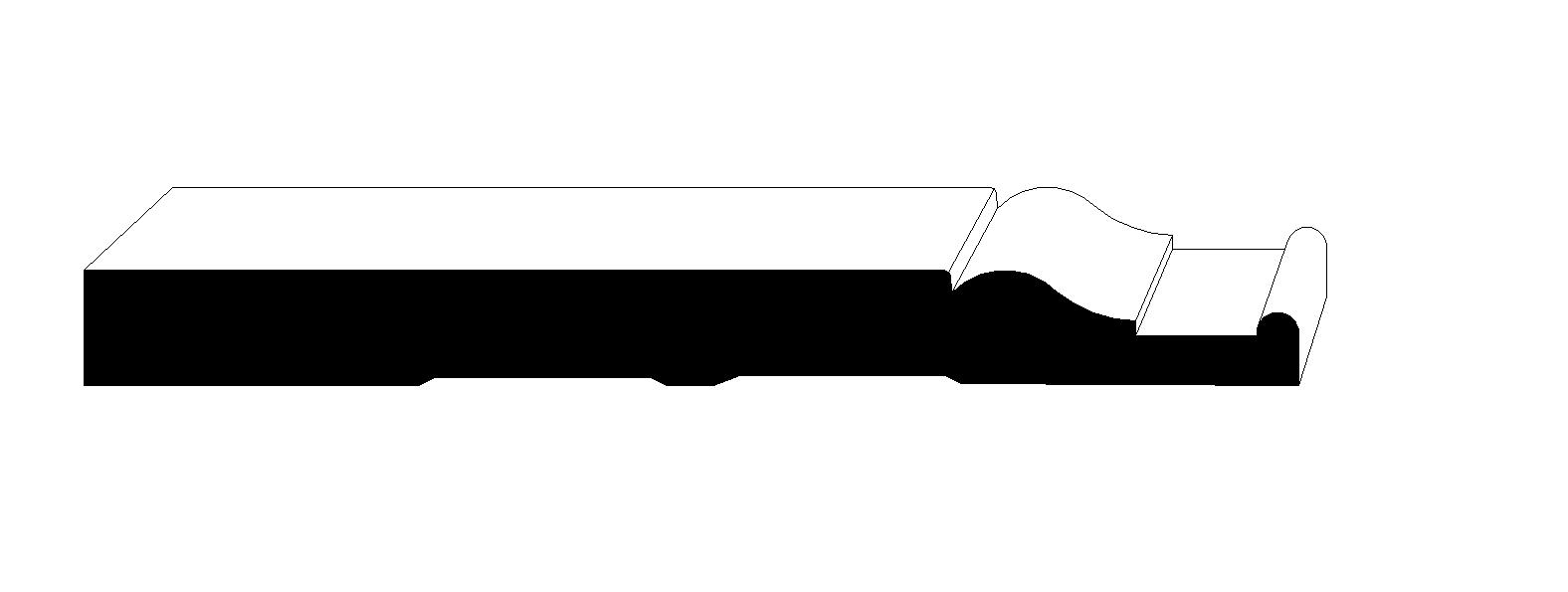

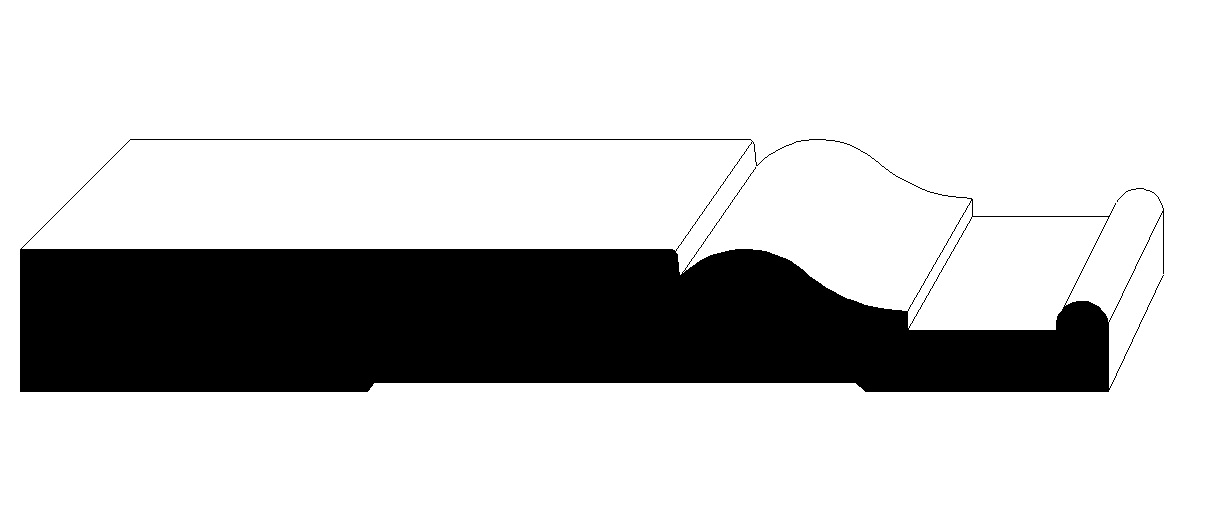

This base cap moulding is used on top of dimensional baseboard to give a plain baseboard a more finished, and decorative look. It is also used in a wide variety of cabinet making and trimwork projects. Its often used as a large inset panel moulding on wainscotting panelled walls.

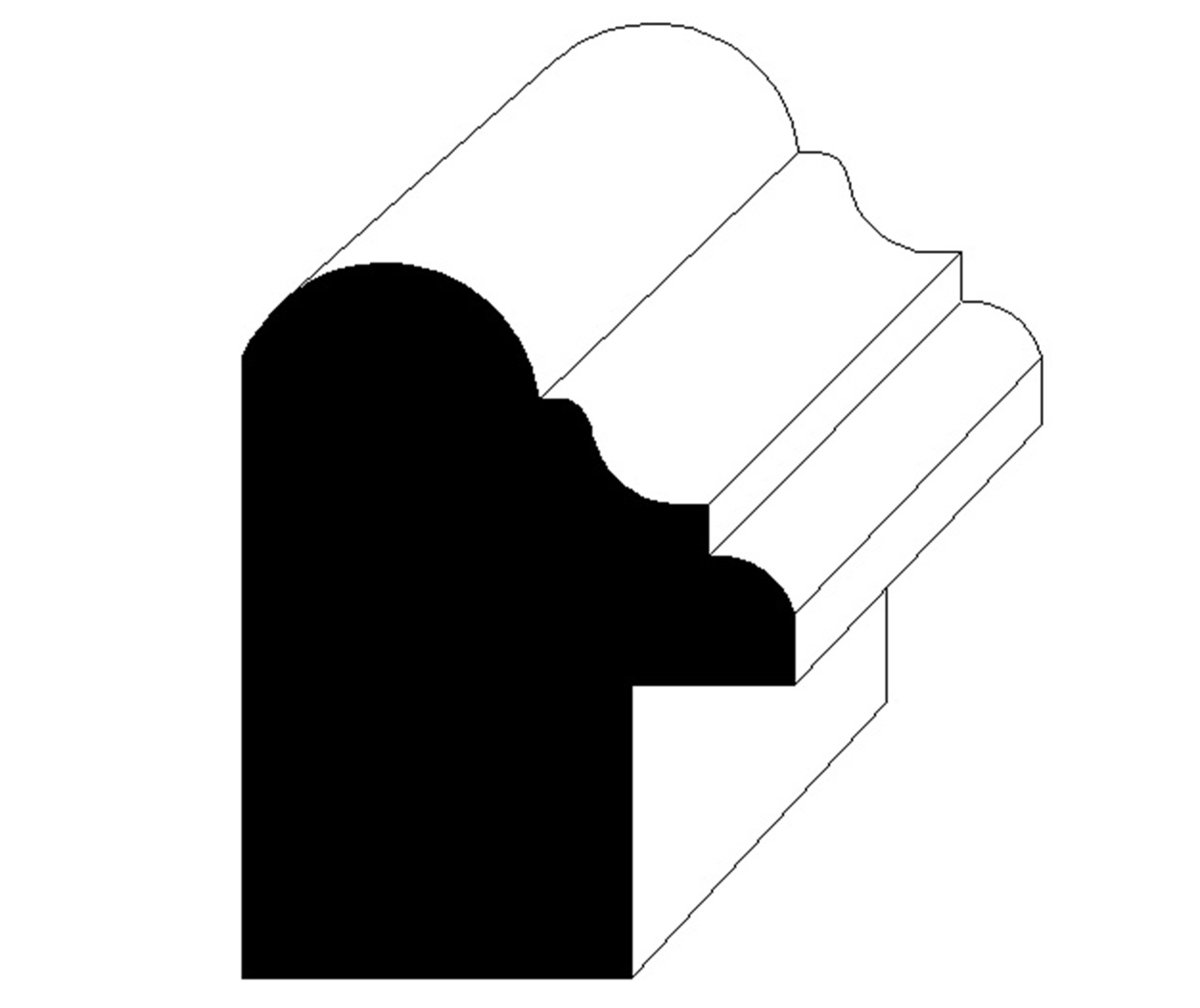

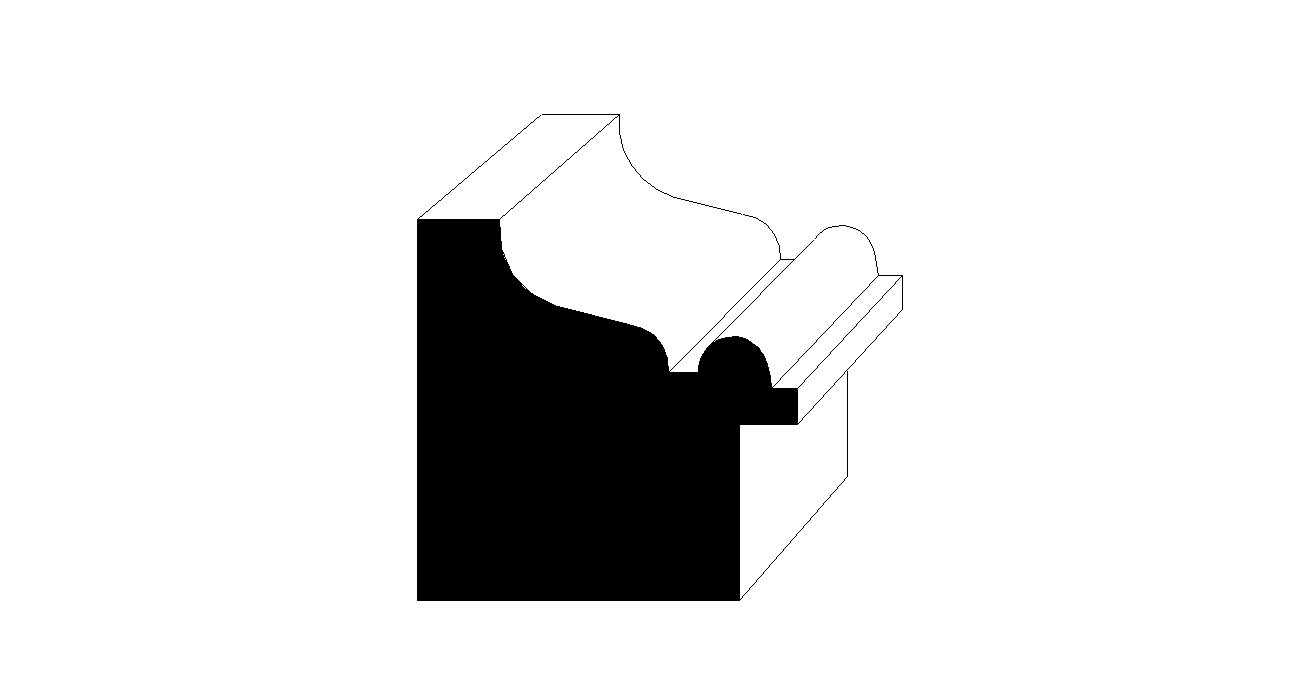

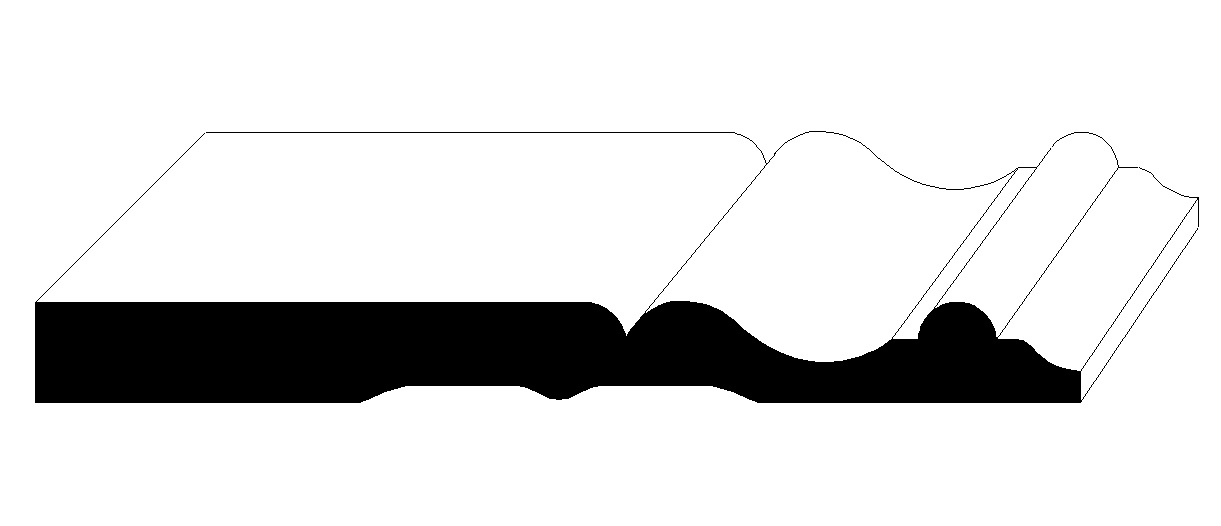

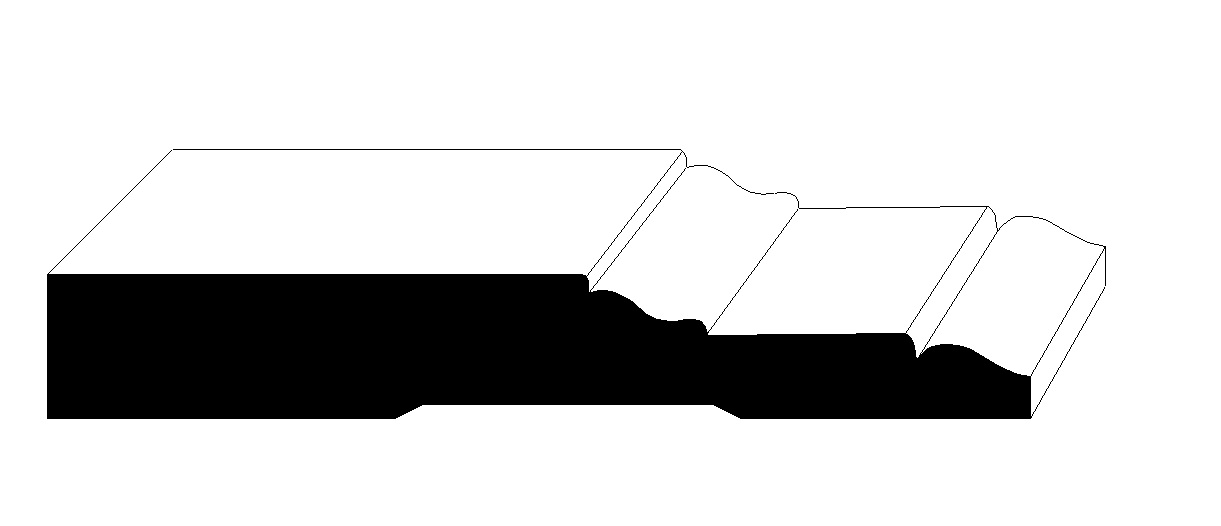

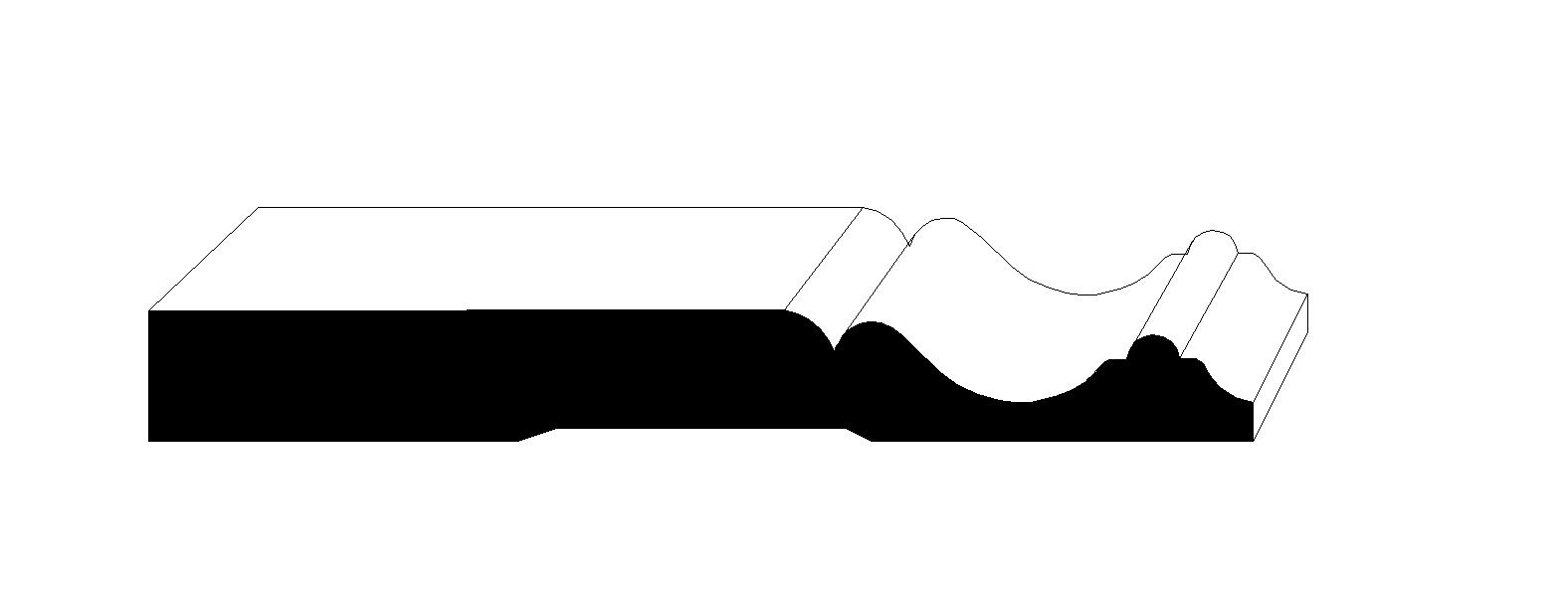

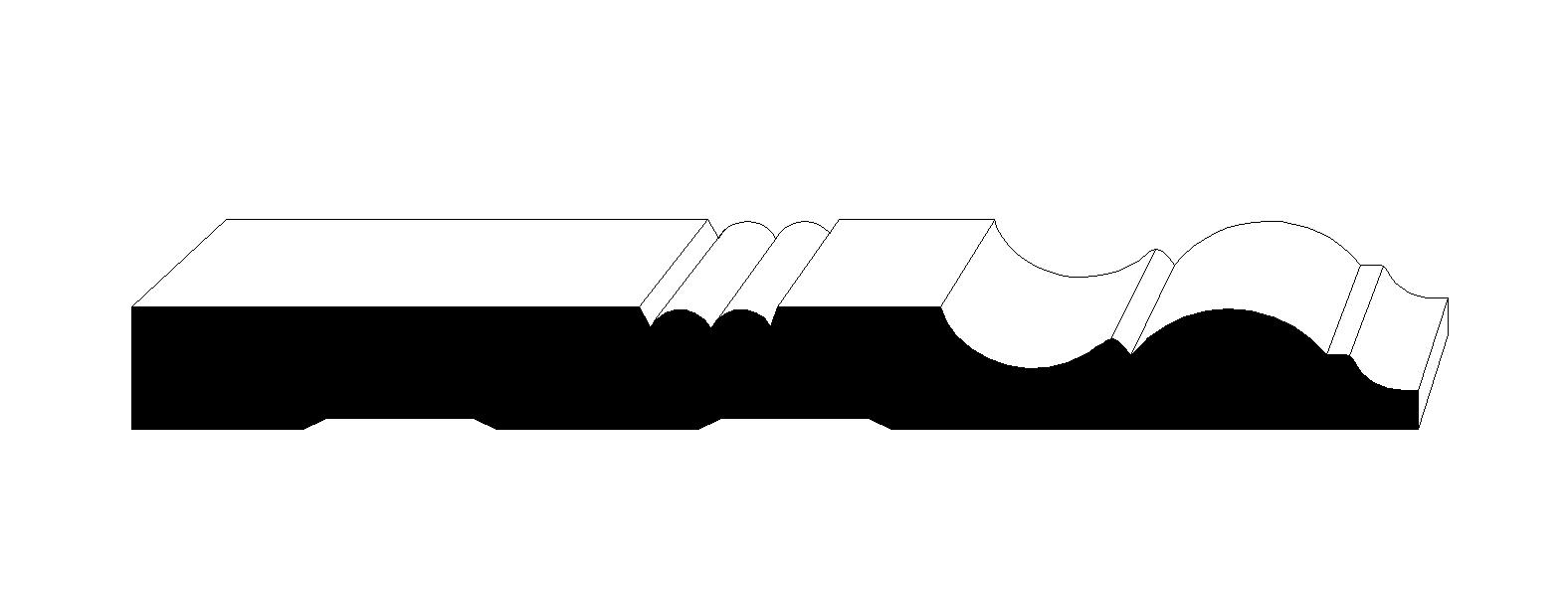

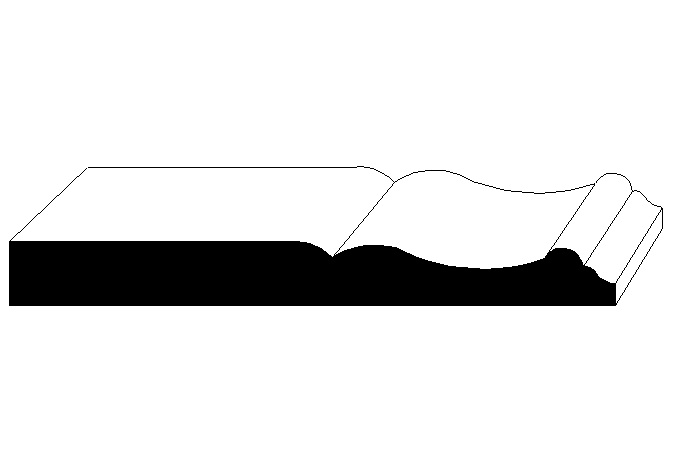

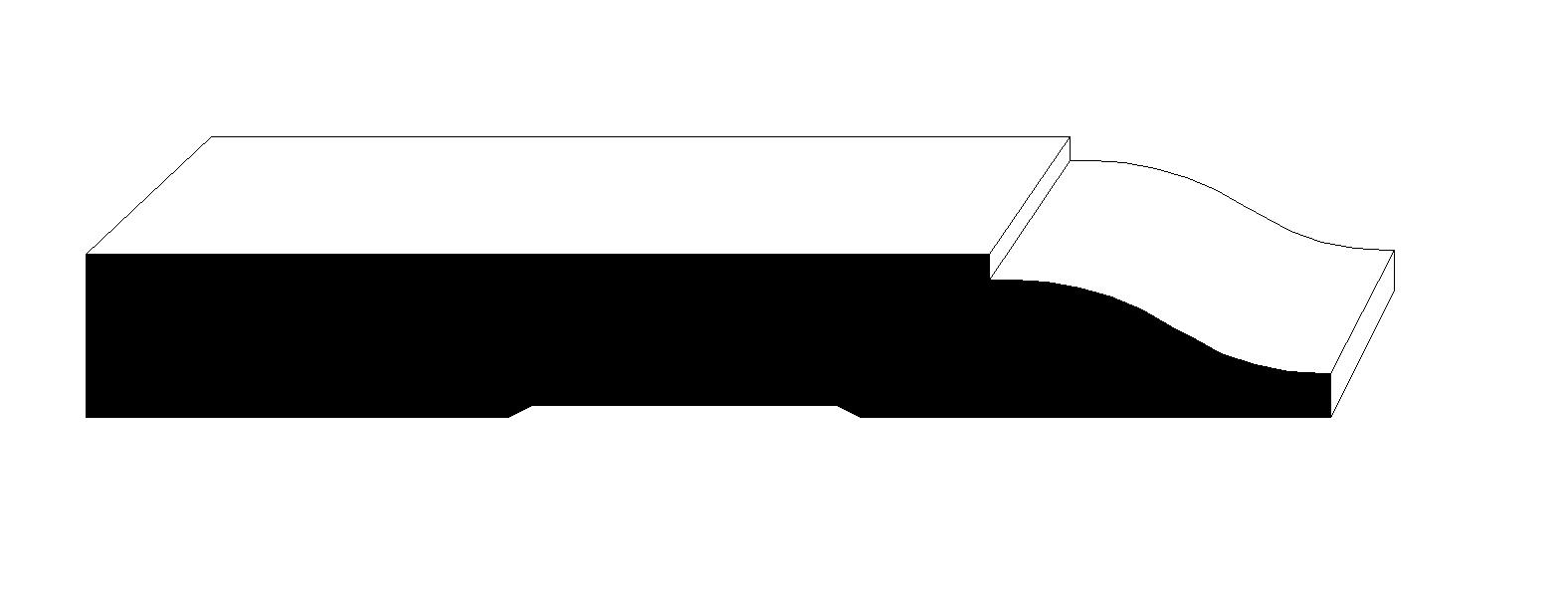

This 7-1/4″ ornamental baseboard offers a decorative substitute to the classic colonial style baseboard. It ties the wall and floor together offering a visual foundation. It protects the walls from bumps and cleaning. The baseboard should compliment the style of casing and should be thinner and wider than the casing. Shoe mould often accompanies the baseboard if the floor is uneven or there is gaps between the baseboard and the flooring.

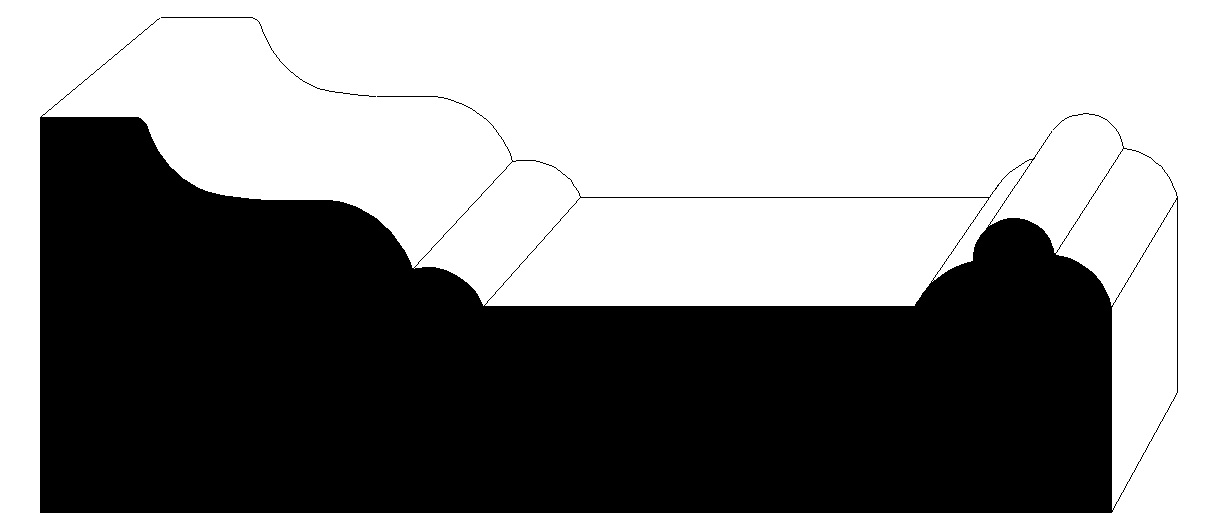

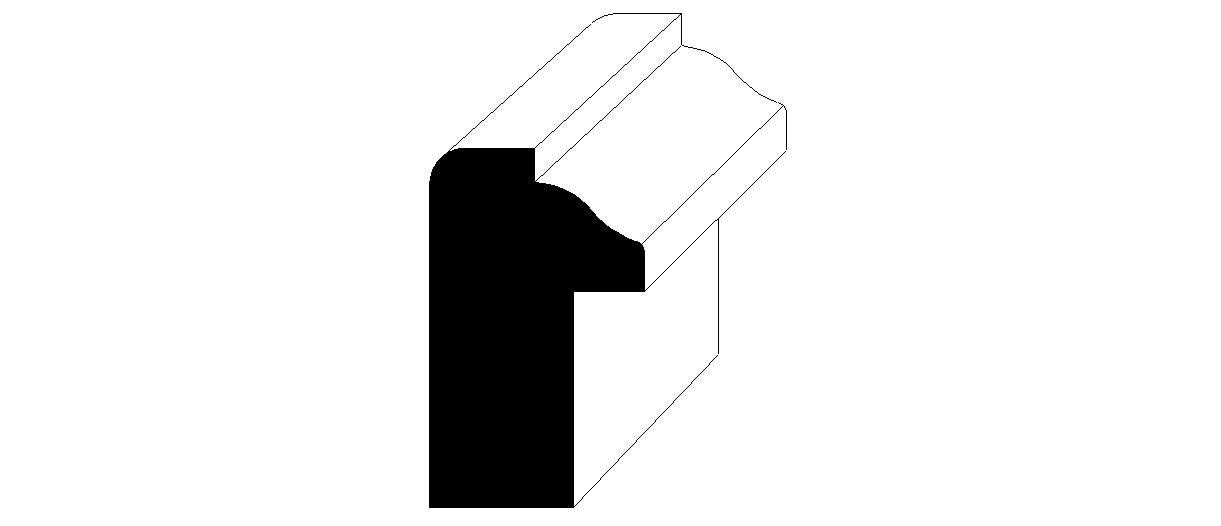

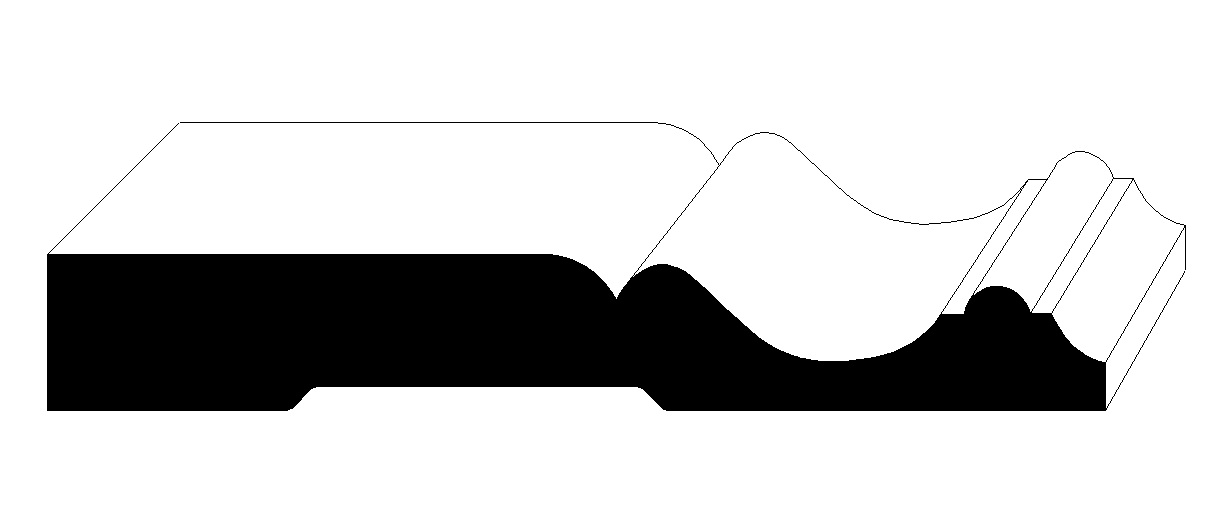

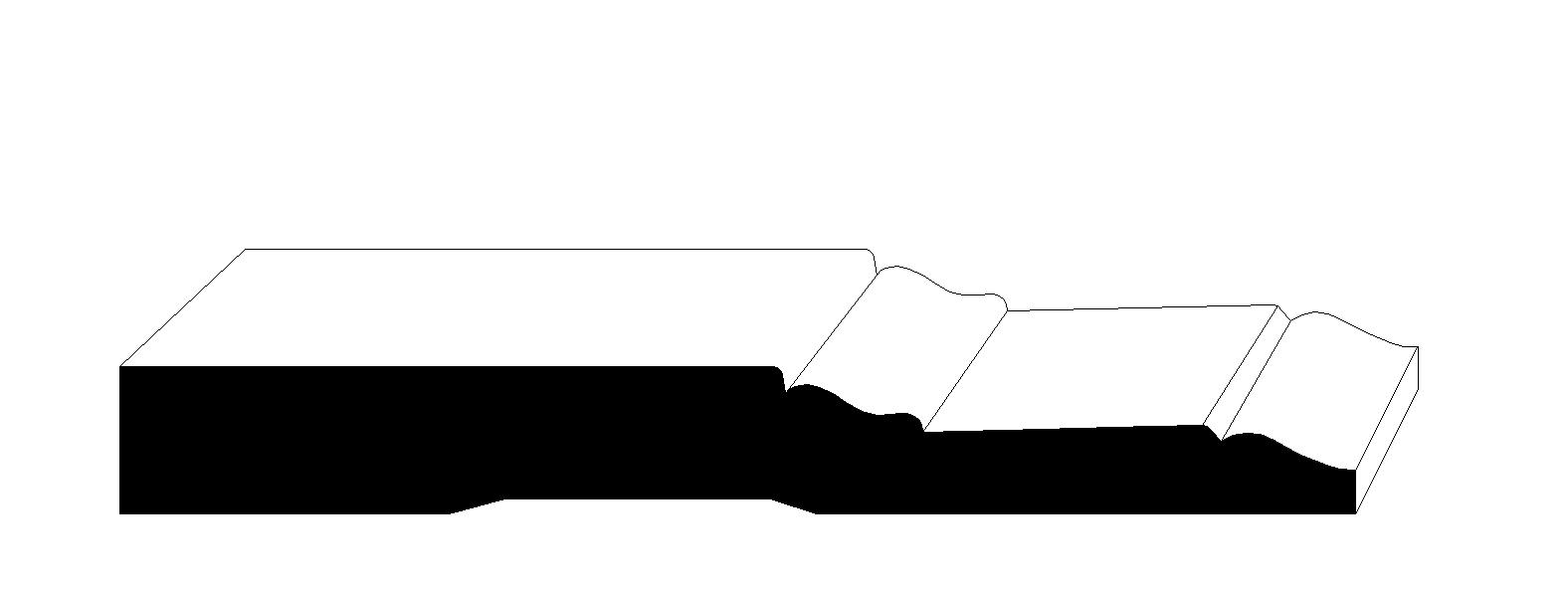

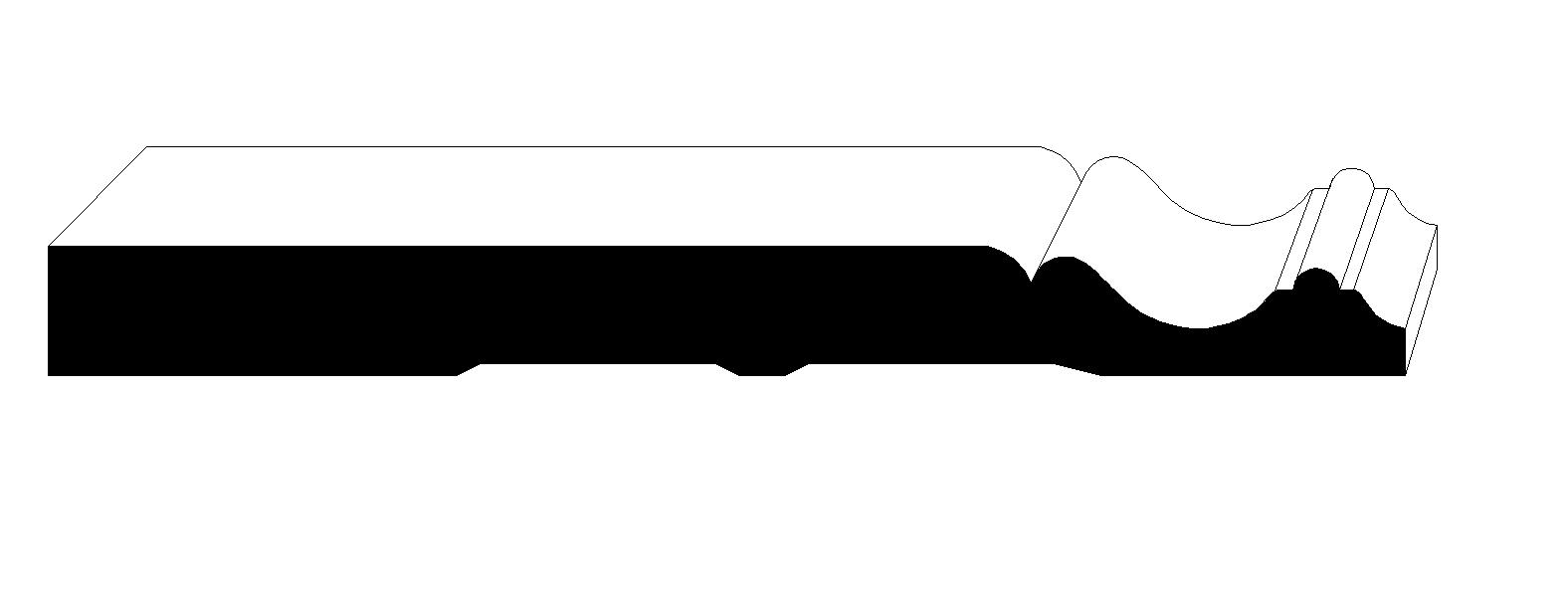

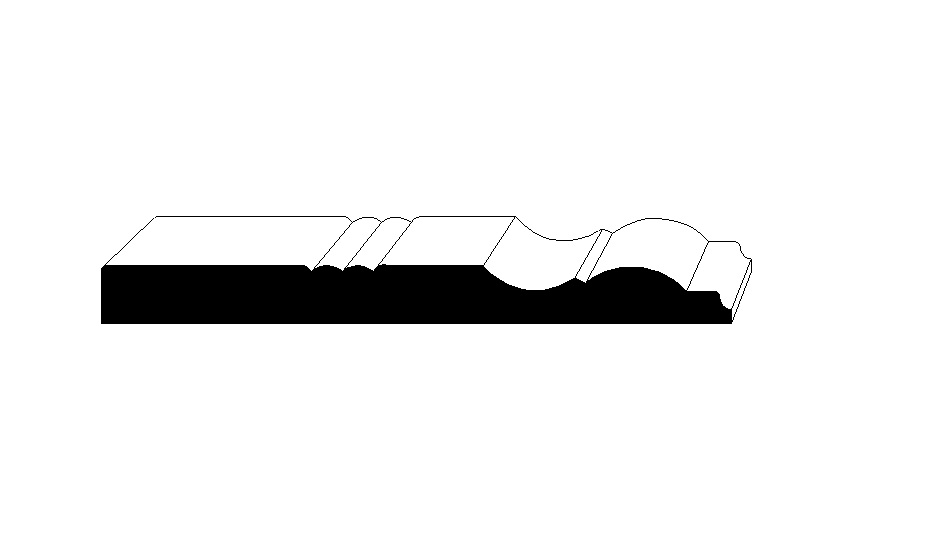

This large decorative baseboard commands a presence in any room. Baseboard ties the wall and floor together offering a visual foundation. It protects the walls from bumps and cleaning. The baseboard should compliment the style of casing and should be thinner and wider than the casing. Shoe mould often accompanies the baseboard if the floor is uneven or there is gaps between the baseboard and the flooring.